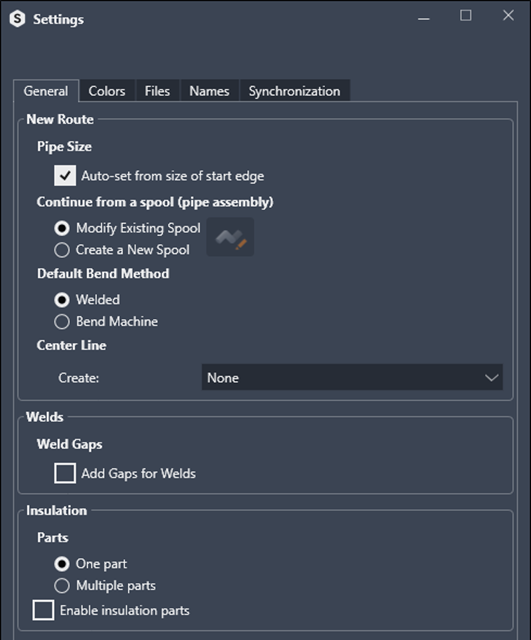

General

User can set preferred settings.

If settings are greyed out its because the Admin have set restrictions for these settings.

New Route

Pipe Size - Auto-set from size of start edge will suggest a pipe size that is closest to the diameter of selected start edge.

Continue from a spool (pipe assembly) – When continue from e.g. a Tee connection you can continue adding pipes and fittings Modifying Existing Spool or Create a New Spool.

Default Bend Method – Set whether you want to weld elbows or bend the pipe as preferred option when both options are available for the pipe run.

Center Line option can be set to None or In part file. To display a center line in spool assembly drawing use this option.

Welds

Weld Gaps – Tick the box Add Gaps for Welds to automacilly add a weld gap according to what is configured in the Spec Editor.

Insulation

Parts – One part option will only create only one part file for insulation for selected pipeline. Multiple parts will create one insulation part for each pipe piece.

By default, insulation is transparent and not Enabled (Inventor option in model browser) when it’s created. To set it Enabled by default active this option.

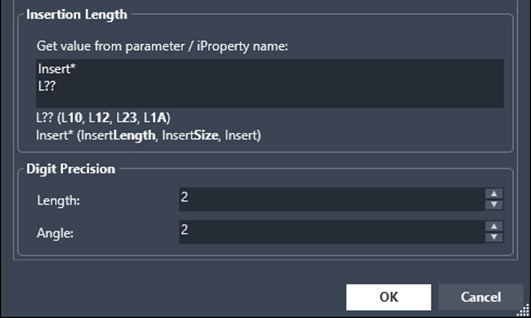

Insertion Length

Get value from parameter or iProprties – When placing a component with Insert Any command get value from a defined parameter or iProperty to set the correct engagement length between pipe and component.

Decimal Precision

To display more decimals in all dialogues that displays a Length or Angle, increase the number of decimals.